Catawater is a one-of-a-kind organic catalyst

The synergy of nature and technology

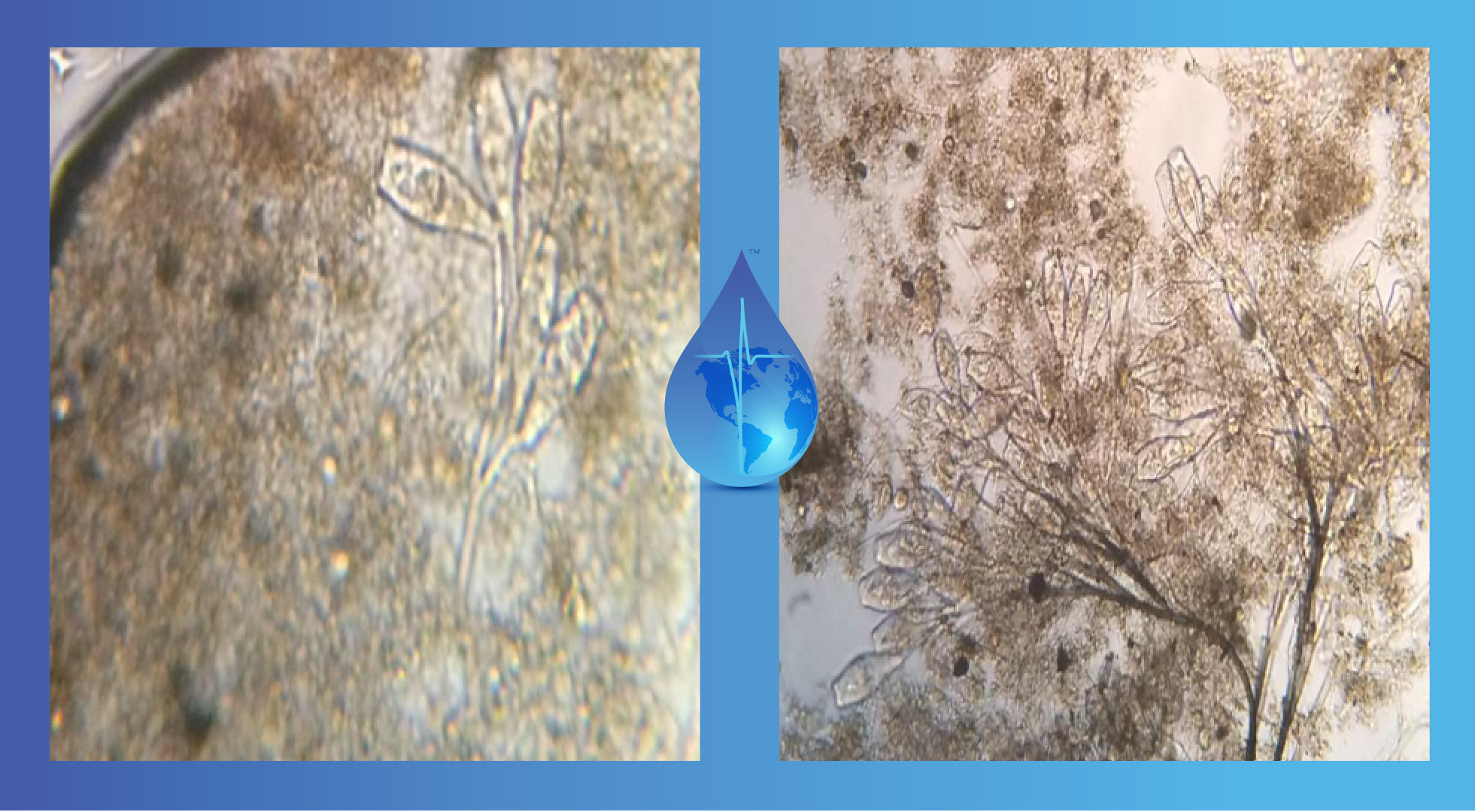

Our biocatalyst enhances what nature creates with non-toxic impacts to the environment.

OUR SERVICES

We help make nature work for you.

Oil & Gas

Works synergistically with environmental elements to dramatically accelerate natural processes.

Wastewater

Works seamlessly with environmental elements to dramatically accelerate natural processes.

Agriculture

Processes accelerated include nitrogen fixation and biomass decomposition, mineral and other nutrient uptake.

A significantly lower cost

This technology, because it is organic, is available at a significantly lower cost than traditional technologies.

In our world, right now, exists a proprietary organic technology that is as safe, versatile, and ubiquitous as water.

It is being used to clean up our environment and convert specific industries into safer, healthier operations that can co-exist harmlessly within the environment.

This same technology is also being used to produce more abundant and healthier food sources for the betterment of mankind.

If you would like to see how this fascinating new technology is making our world a more sustainable environment, click the link below.

A New Innovative Approach To Organic Solution Management

Because Catawater is an organic nano-technology, the cost to manufacture it is much less than conventional products, which translates into cost savings to you. As there is no shelf life on this product, there’s no loss due to waste. And most conveniently, there are no special requirements for adaption. It is simply injected like any other natural element.

Oil & Gas Solutions

These bio-catalytic processes have proven effective in numerous field studies for a wide range of applications, representing major cost reductions and lowering the environmental impact of the oil & gas industry.

Some benefits include reducing the carbon footprint of oil sands production, generating carbon credits, mitigating tailings residues and remediating tailings pollution, and reducing greenhouse gases.

Oil & gas solid waste facilities which practice landfill and/or land farming operations may benefit by utilizing Catawater to possibly eliminate the use of mechanical processes.

Operating costs can be reduced by as much as 60% depending on the unique design and SOP’s of each respective operation.

Catawater works synergistically with environmental elements to dramatically accelerate natural processes.

- Ionically extracts bitumen at significantly increased levels from oil sands using a “no heat” process.

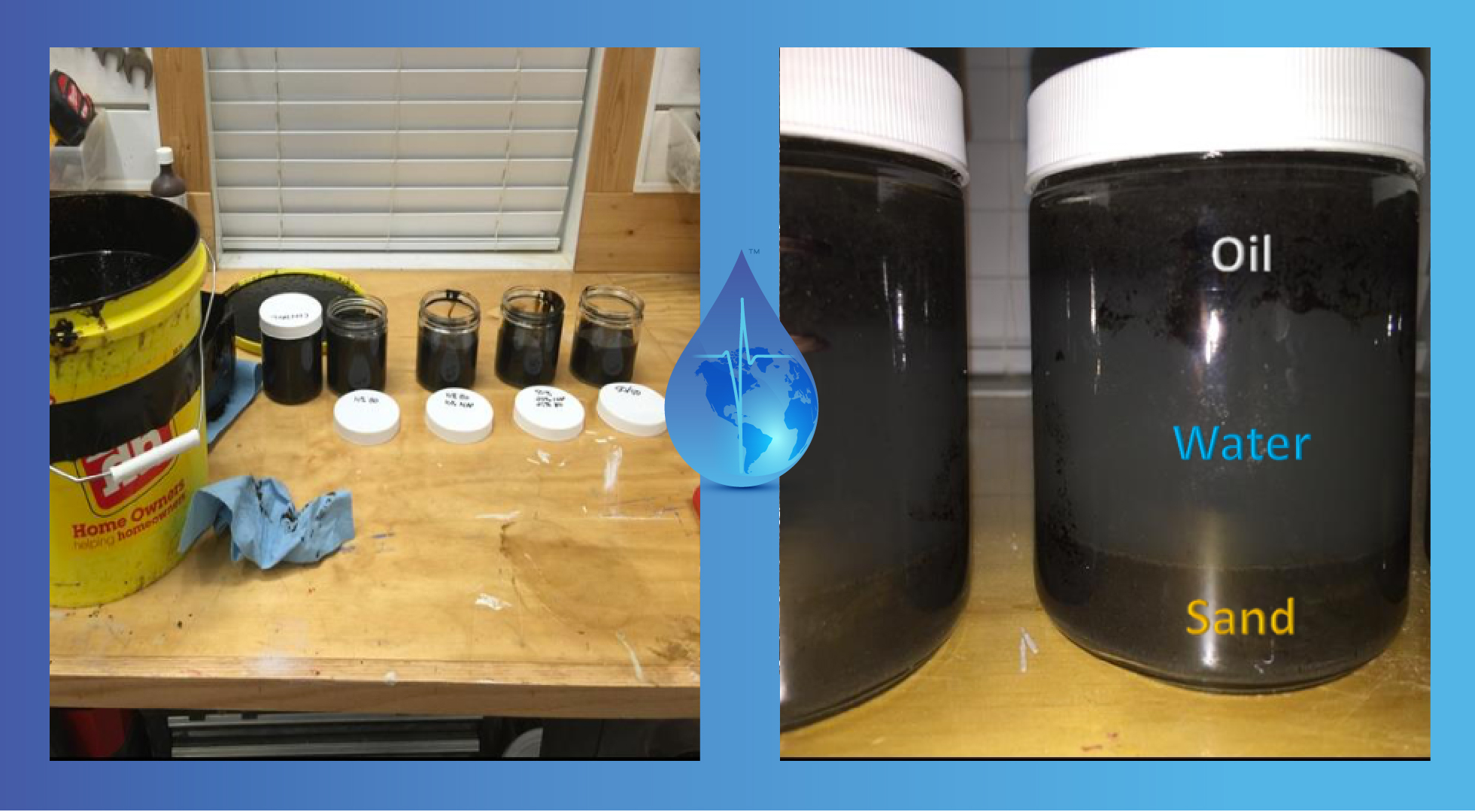

- Remediates tailing ponds to recover oil and water.

- Removes hydrogen sulfide from oil and gas streams.

- Well stimulation.

- NORM reduction and elimination.

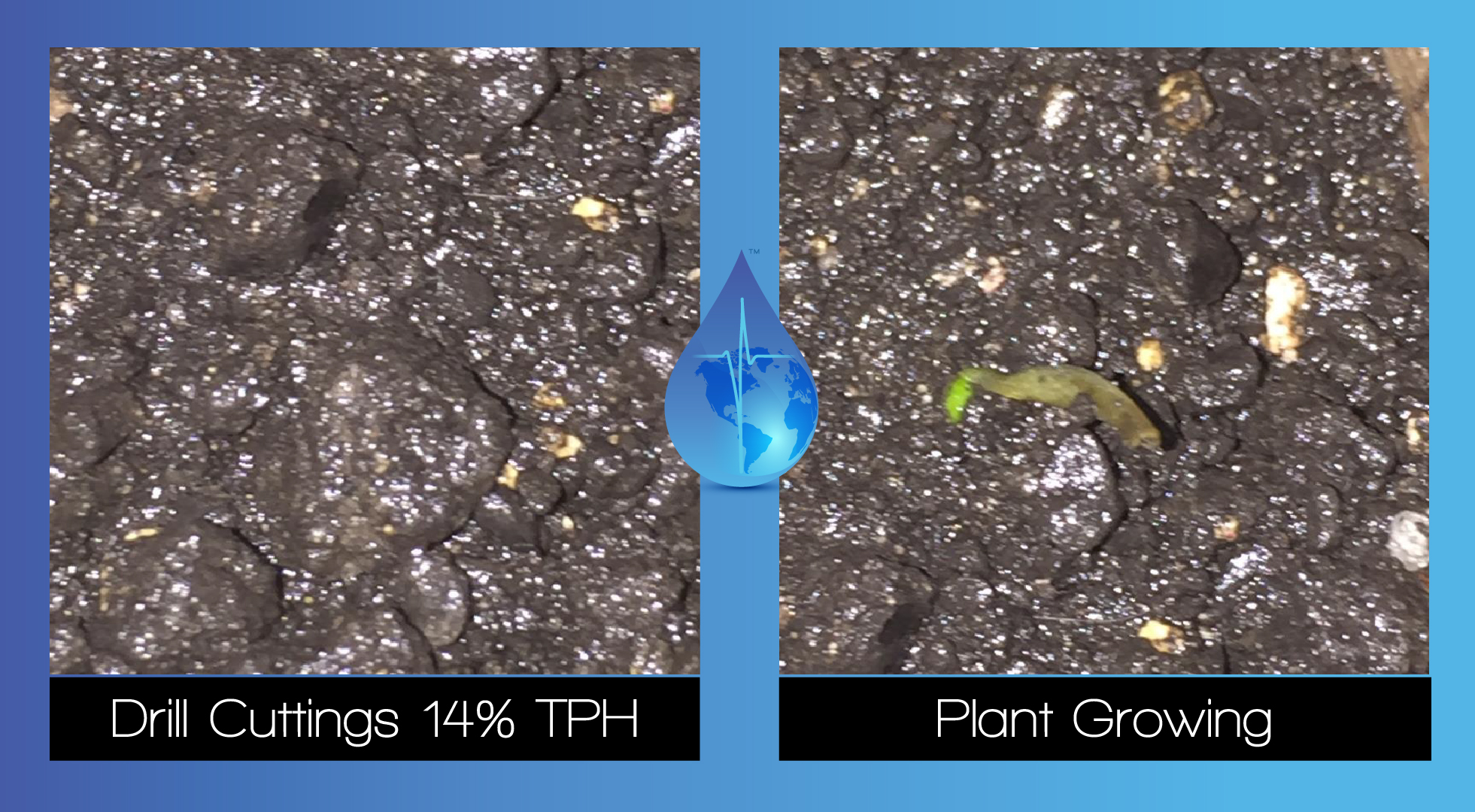

- Remediates surface soil contaminated with salt, oil spills, and other contaminants.

- Produced water recycling.

- Increases production via Enhanced Enzyme Oil Recovery method.

- Heavy oil treatment. for increased viscosity and pipeline flow.

- Eliminates H2S from petroleum oil and gas streams (can be implemented in scrubbers).

- Less than 1% retention on OBM cuttings.

- Drill cuttings are rendered inert.

- And more.

- Saltwater disposal well treatment.

- Minimize or eliminate the use of inorganic chemicals.

- Reduces injection pressure.

- Higher quality skim oil.

- Complete separation of solids, water and oil.

- And more.

Wastewater Solutions

Catawater works seamlessly with environmental elements to dramatically accelerate natural biological processes.

The net effect of this acceleration ultimately results in the optimization of midstream water quality which translates into operational cost savings, capital deferment, reduced power consumption, asset sustainability, plant efficiency, and overall “cleaner” easily managed operations.

Our customers experience amazing results without the addition of large-footprint mechanical solutions which add costs.

Catawater is simply introduced into the waste stream or process water’s existing infrastructure and operation like any other organic element so there are no required retrofits.

Substantial short and long term savings of up to 50-70% are awaiting your operation as well. Contact us to talk about it!

- Ionically extracts bitumen at significantly increased levels from oil sands using a “no heat” process.

- Remediates tailing ponds to recover oil and water.

- Removes hydrogen sulfide from oil and gas streams.

- Well stimulation.

- NORM reduction and elimination.

- Remediates surface soil contaminated with salt, oil spills, and other contaminants.

- Produced water recycling.

- Increases production via Enhanced Enzyme Oil Recovery method.

- Heavy oil treatment. for increased viscosity and pipeline flow.

- Eliminates H2S from petroleum oil and gas streams (can be implemented in scrubbers).

- Less than 1% retention on OBM cuttings.

- Drill cuttings are rendered inert.

- And more.

- Saltwater disposal well treatment.

- Minimize or eliminate the use of inorganic chemicals.

- Reduces injection pressure.

- Higher quality skim oil.

- Complete separation of solids, water and oil.

- And more.

Agriculture Solutions

- Increase animal weight gain and decrease death loss.

- Treat holding facilities to eliminate odors and flies.

- Treat waste lagoons to generate methane gas for on-site use.

- Treat waste lagoons to eliminate hydrogen sulfide odor.

- Treat waste lagoons to eliminate solid waste build-up.

- Increases production via Enhanced Enzyme Oil Recovery method.

- Heavy oil treatment. for increased viscosity and pipeline flow.

- Eliminates H2S from petroleum oil and gas streams (can be implemented in scrubbers).

- Less than 1% retention on OBM cuttings.

- Drill cuttings are rendered inert.

- And more.

Our Partners & Customers